Bespoke Rings & Custom Jewelry Direct from Manufacturer

In-House Plating for Guaranteed Quality

Jewelry Certificate

Custom Jewelry Manufacturing Services With NDA

We strictly protect our clients’ privacy and intellectual property. A signed NDA ensures your designs remain 100% confidential throughout the production process. Your trust and ideas are safe with us.

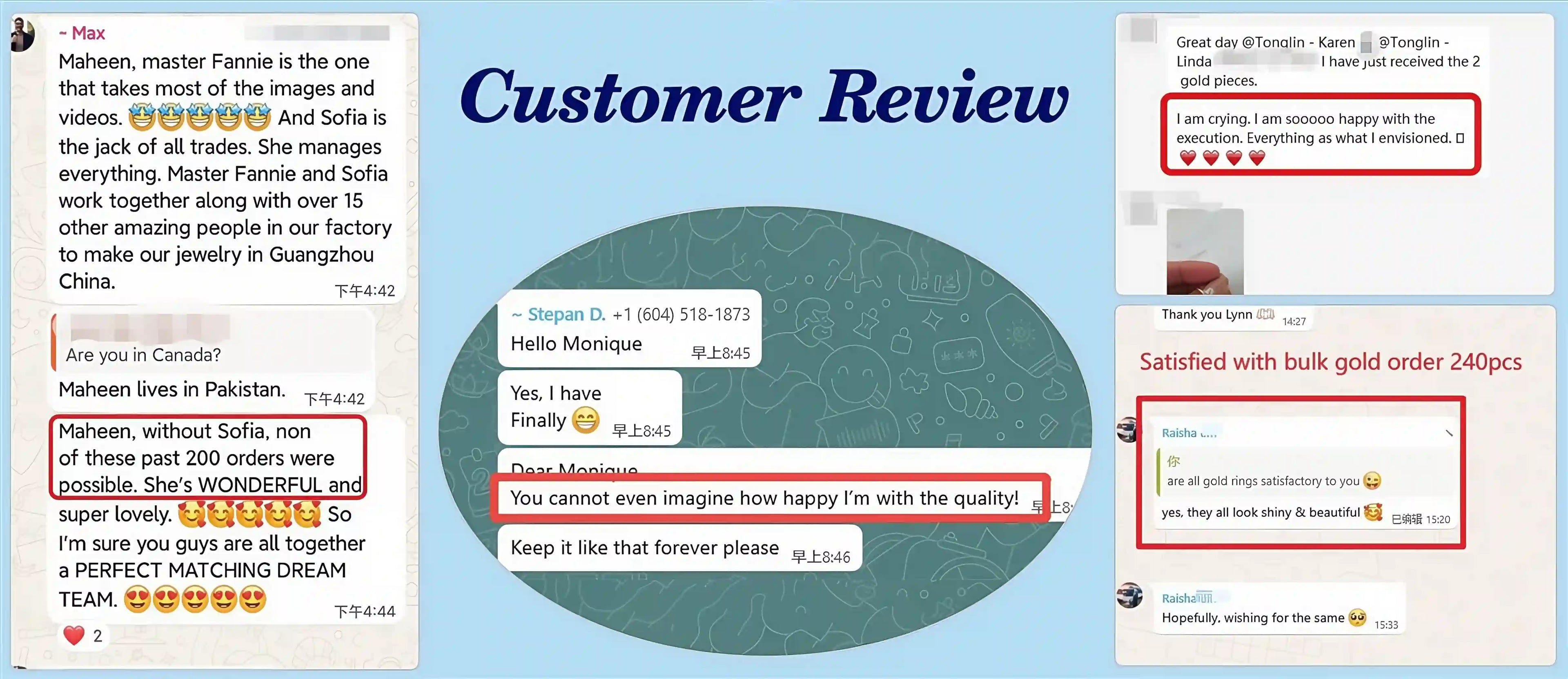

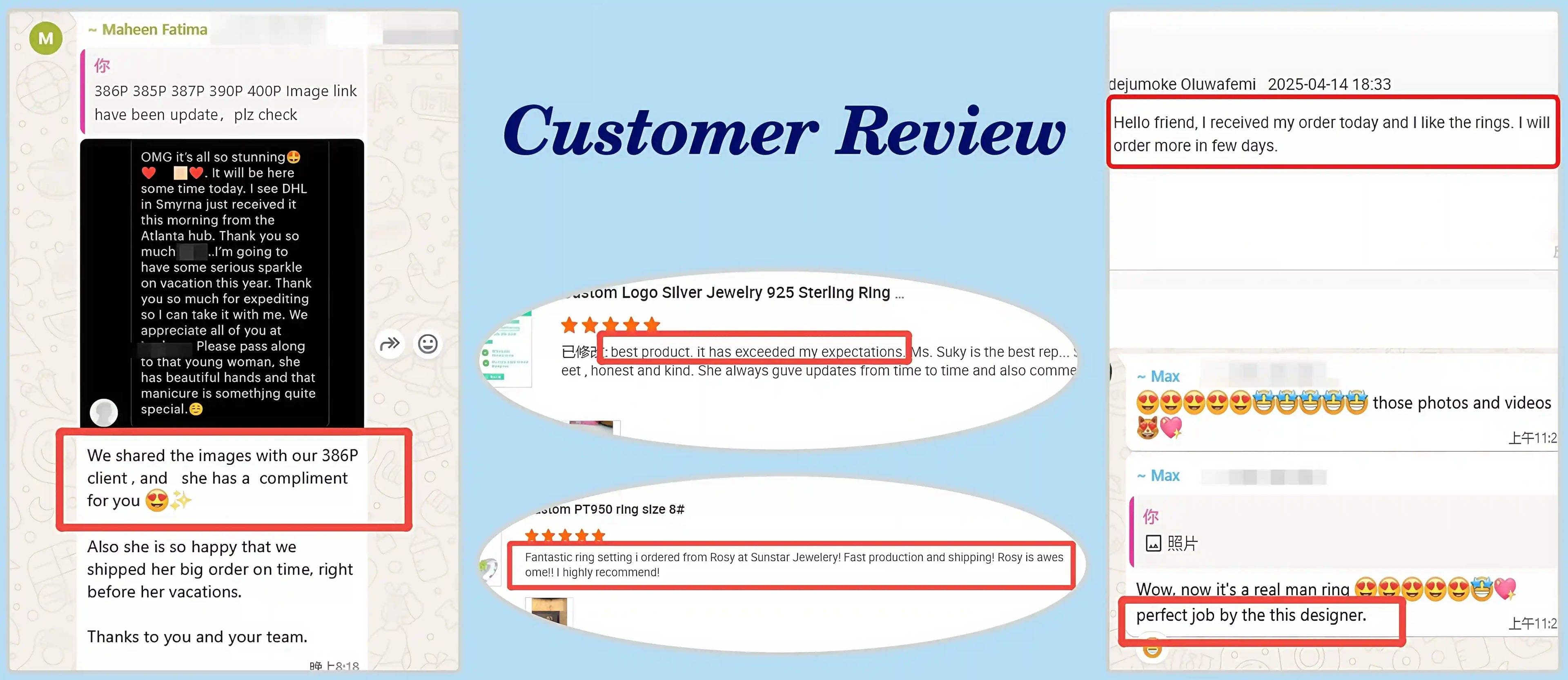

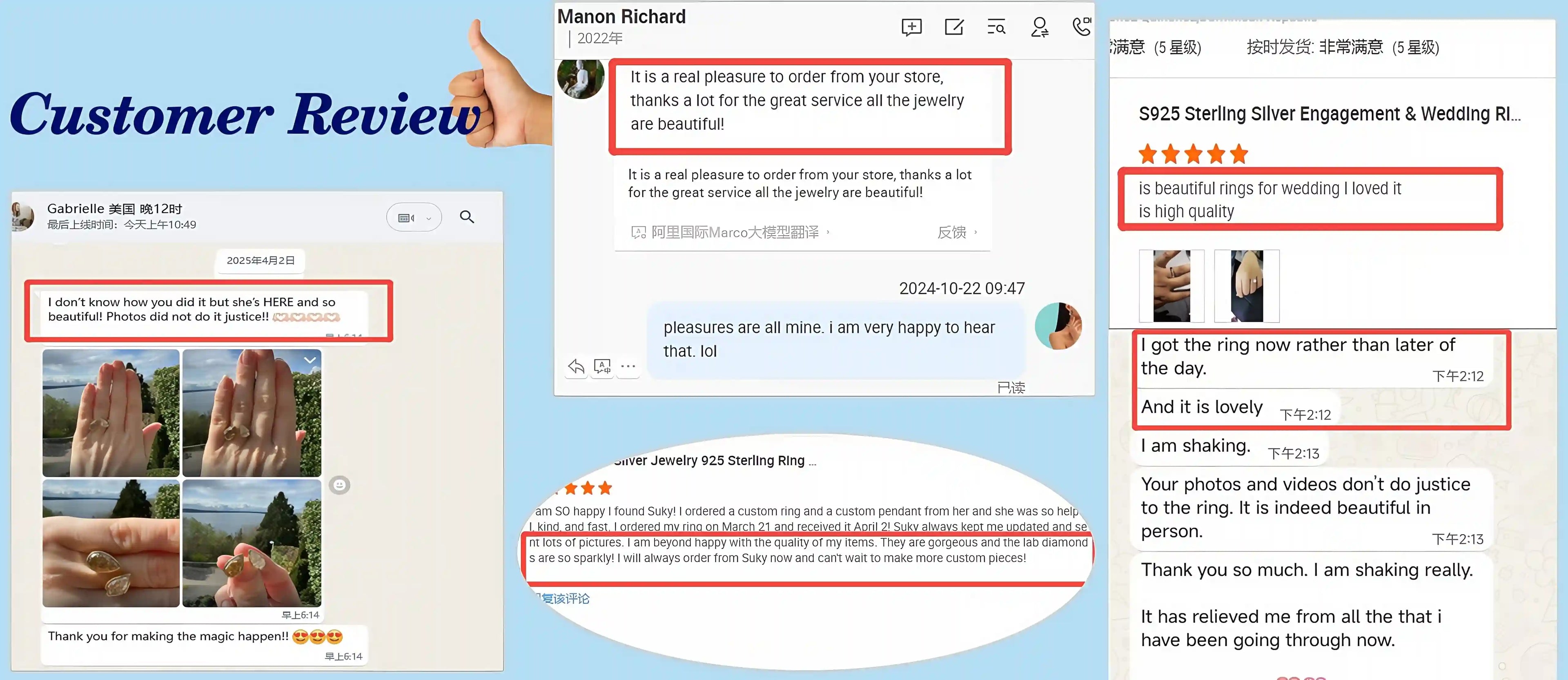

Success Stories

Trusted by Designers & Startups Worldwide

Jewelry Manufacturing Excellence: 15,000+ Pieces Daily

Our factory specializes in custom jewelry and bespoke rings for individual and business clients.

Our Custom Jewelry Ordering Process

How Our Custom Jewelry Design Process Works

-

step 1

Hand-Drawn Sketch

Begin with a hand sketch to shape your jewelry vision.

-

step 2

3D Printing for Waxing Mold

A wax model is created through 3D printing or skilled sculpting to capture every detail.

-

step 3

Accurate the Brass Mold

We refine the brass mold for precise mass

production.

-

step 4

Waxing Injection for mass production

Wax replicas are made for silver casting.

-

step 5

Casting wax parts to Silver

Wax models are cast into silver, shaping the final design.

-

step 6

Gate Cutting

Excess silver is trimmed to reveal the jewelry’s shape.

-

step 7

Polishing

Polished to a smooth, shiny finish-enhancing beauty and

detail.

-

step 8

Electroplating

Electroplating uses electric current to apply a shiny, durable metal layer.

-

step 9

Cosmetic Secondary Work

Final touches like inlay or engraving personalize each piece.

-

step 10

Packing

Your jewelry is packaged carefully, ensuring it arrives in perfect condition.

Design Your Dream Jewelry — From Unique Rings to Custom Creations

Why Choose Tonglin for Custom Jewelry Design?

-

Free Design

Get custom 3D CAD designs for free—direct from our factory with expert support.

-

MOQ 1 PC

We offer a custom jewelry MOQ of just1, perfect for startups and independent designers.

-

NDA

We guarantee full confidentiality—your custom designs and information are always safe with us.

-

100% Quality Assurance

100% full inspection and strict quality control ensure 99.5% pass rate and excellent quality.

カスタマイズに関するよくある質問

材料

1. 925 スターリングシルバー、防水、変色なし、低刺激性、6 か月~ 3 年間色を保持。

2. 316/316L ステンレス鋼、防水、変色防止、6 か月~ 3 年間の色保持。

3. 10k、12k、14k、18k、24kの純金。

弊社には豊富な石材のライブラリがあり、お客様のニーズに合わせてさまざまな素材をご提供できます。

最小注文数量

1. カタログデザインの場合、MOQはデザインごとに5個となります。

2. カスタマイズされたデザインの場合、最小注文数量は 60 ~ 100 個になります。

詳しい内容につきましては、弊社営業チームまでご確認ください。

How do you ensure product quality before shipping?

Every piece of jewelry undergoes a full inspection before shipment. Our quality control team carefully checks for craftsmanship, durability, and stone settings to ensure the highest standards.

What is the warranty period for your jewelry?

We offer a one-year warranty on all our jewelry. If you experience any quality issues within this period, we provide free returns and exchanges to ensure complete customer satisfaction.

Do you offer after-sales support?

Yes! We provide lifetime after-sales service for all our products. Whether you need maintenance, repairs, or assistance with your jewelry, our team is always available to help.

How do you protect the confidentiality of custom designs?

We highly respect our clients' intellectual property and design rights. For all custom orders, we provide a Confidentiality Agreement (NDA) to ensure that your designs remain exclusive to you. We will never share, reproduce, or use your custom designs without your explicit consent.